L&D / Training

Knowledge Automation for Training.

Find out how L&D professionals are using technology to prepare for the great crew change, improving operator qualification & manufacturing onboarding for the next generation of staff.

Challenges

By 2030, 75% of senior SMEs will have retired.

L&D professionals are under pressure to fill the knowledge gap & onboard new operators faster & more efficiently. Whether it’s operator qualification, manufacturing onboarding or improving operational discipline – digital replicas can help on your journey.

Challenges

By 2030, 75% of senior SMEs will have retired.

L&D professionals are under pressure to fill the knowledge gap & onboard new operators faster & more efficiently. Whether it’s operator qualification, manufacturing onboarding or improving operational discipline – digital replicas can help on your journey.

Mass

retirements.

Personnel churn, causing a loss of organizational knowledge.

SMEs

overstretched.

Existing SMEs already pulled in many directions internally.

Slow & inefficient

onboarding.

Difficulties to digitalize the onboarding process for newer operators.

Our Solution

Procedure clarity, delivered.

Voovio’s software uses digital replicas, procedure simulators and a field execution tool (FET) to speed up the operator qualification process:

Accessible 24/7/365

Digital replicas provide your real plant on any device, accessible 24/7/365

Easy shareable

Shareable on virtual platforms for operations meetings; rack-up meetings; TAR planning & maintenance.

Remote learning

Learn & practice SOPs remotely with simulators.

Remote evaluation

Assign & assess remotely with our test simulator.

Visual SOP guide

Visual SOP guide to ensure quality execution in the field.

Onboarding accelerated

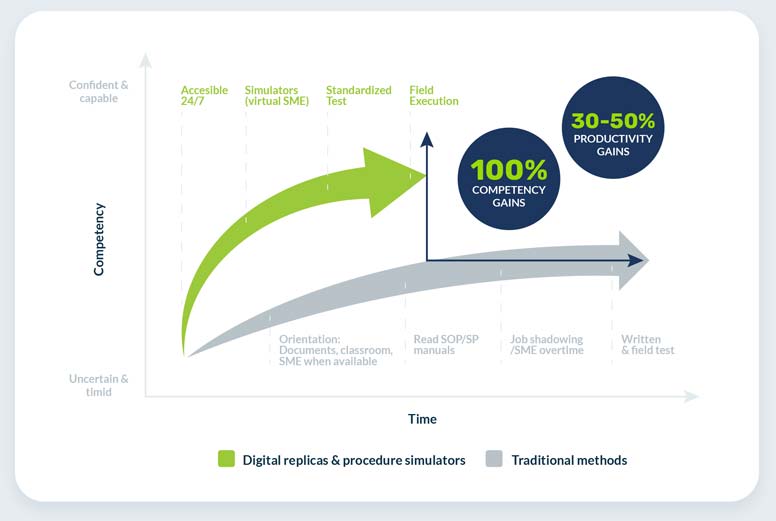

More knowledge in less time.

Voovio enables operators to gain more knowledge, in less time, at a lower cost to your organization.

RESULTS

Adopted by market leaders.

Voovio isn’t just another flashy technology solution claiming to make operator onboarding easier. It’s tried & tested by market leaders such as Dupont & Chevron Phillips.

L&D team at large Petrochemical Plant

Challenge

The L&D team was tasked with the challenge of high attrition, needing to improve operator onboarding efficiency, operational discipline and reduce costs. They were also facing a significant amount of unplanned downtime related to boiler feedwater (BFW) pump failures related to misoperation.

How Voovio helped

Using Voovio, they provide a BFW training/refresher prior to execution & have created a new onboarding curriculum for new operators.

L&D team at a US Refinery

Challenge

The L&D team at a refinery needed to reduce overtime to train contract drivers & reduce unplanned downtime on loading racks due to damage and spills in loading areas.

How Voovio helped

3rd party truck drivers are remotely trained and assessed prior to loading.

Nonwovens Petrochemical Plant in the US

Challenge

Operations leaders at petrochemicals plant (nonwovens) in the US needed to eliminate incorrect process start-ups & avoid low product yield due to operator execution errors.

How Voovio helped

Using procedure simulators prior to startup, as well as enhanced views & field execution tool (FET) during startup.

CONTACT