Maintenance

Knowledge Automation for Maintenance.

Worried about the risks that come with turnarounds & shutdowns? See how knowledge automation technology can reduce costs & ensure efficiency in the maintenance process.

Challenges

Turnarounds cost the process industry billions of dollars per year.

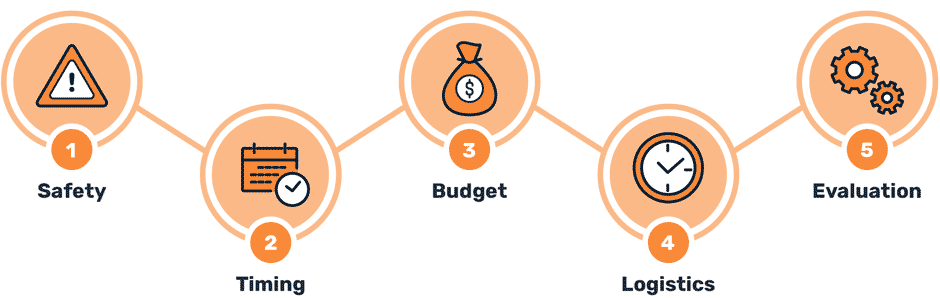

Turnarounds & shutdowns are a headache for plant managers and operations leaders in the process industry. When it comes to implementing a shutdown or turnaround, you need to consider:

Our Solution

Reduce the impact of turnarounds & shutdowns.

Voovio’s knowledge automation technology can reduce costs & the disruption of turnarounds in three ways:

Feeds Off

- Operators can refresher train on shutting down & clearing critical complex, & infrequent equipment & systems, mitigating the risk of SHE incidents.

- Operators can be assessed for competency prior to being assigned to perform critical & complex tasks, minimizing the risk for SHE incidents.

- Operators can utilize the “toolbox” feature to isolate & clear up with the correct bleeders, hoses and hose fittings, avoiding trapped process materials & spills resulting in environmental incidents & potential fines.

- Operators can utilize FET as a step by step guide to execute S/U tasks in the proper sequence avoiding valving errors, process upsets, etc.

Isolate Equipment

- Operators can use the field execution tool with step-by-step guidance along with the actual picture of the field devices to execute lock-outs, confined space, and line breaks properly, avoiding serious safety incidents.

- Operators can refresher train on isolating critical complex, infrequent equipment & systems, mitigating the risk of SHE incidents.

- An increase in workforce competency expands the pool of operators capable of being able to isolate equipment.

Feeds On

- Operators can refresher train on leak checking & starting up critical complex, mitigating the risk of SHE incidents.

- Operators can be assessed for competency prior to being assigned to perform critical & complex tasks, minimizing the risk for SHE incidents.

- Operators can utilize FET as a step by step guide to execute S/U tasks in the proper sequence avoiding valving errors, process upsets, etc.

- An increase in workforce competency expands the pool of operators capable of being assigned to execute S/D and clear-up of equipment and systems avoiding both costly “waiting” by maintenance workers.

RESULTS

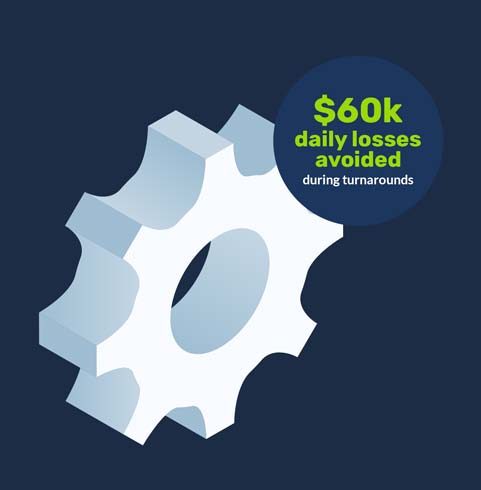

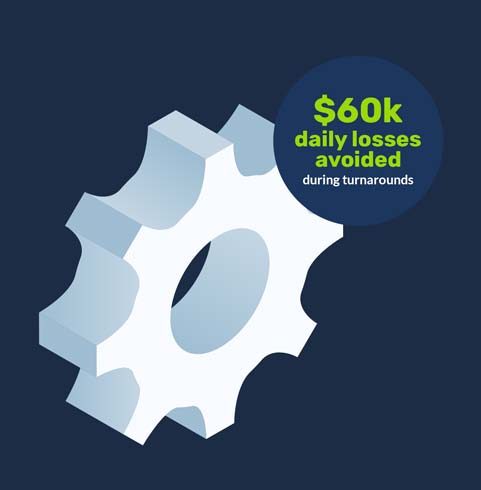

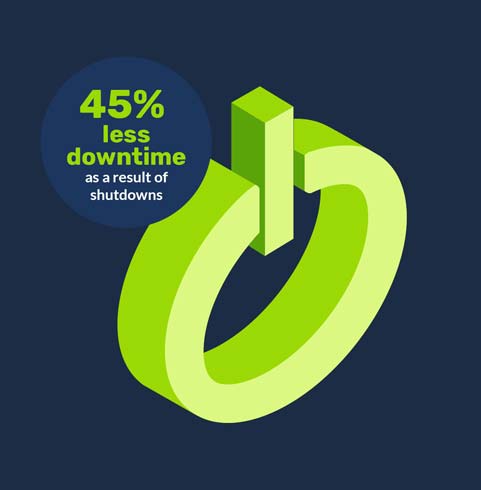

Adopted by market leaders.

Voovio isn’t just another flashy technology solution claiming to prepare your team for turnarounds. It’s tried & tested by market leaders such as Dupont & Chevron Phillips.

Leading US Petrochemical Firm

Challenge

A leading petrochemical firm didn’t have an easy way to prepare for vaporizer shutdowns, suffering in the midst of extensive SME retirements – needing to shutdown equipment just to train new operators.

How Voovio helped

Voovio allowed them to simulate these procedures, using a replica of equipment so there was no longer a need to shut down to train new staff.

US Nonwovens Petrochemical Plant

Challenge

Operations leaders at a petrochemicals plant (nonwovens) in the US needed to eliminate incorrect process start-ups and avoid low product yield due to operator execution errors.

How Voovio helped

Using procedure simulators prior to startup, as well as enhanced views & field execution tool (FET) during startup.

CONTACT