Every year, industrial facilities experience process safety incidents. Despite evolving regulations and protocols, these incidents – along with near misses – persist. As facilities age and extreme weather events increase, pressure on vulnerable assets grows. Process safety management (PSM) serves to reduce incidents, yet safety-critical maintenance often falls behind, and challenges remain. PSM is not just a regulatory requirement but a critical safeguard for protecting lives, assets, and the environment.

Addressing the Key Challenges in Process Safety

Despite growing awareness of process safety, significant gaps remain between goals and execution. According to the latest Sphera Process Safety Report, 66% of respondents acknowledge discrepancies between their companies’ safety targets and actual performance. The report, which gathers insights from 300 process safety professionals across six continents, with an average of 17 years of experience, highlights the industry’s most pressing challenges.

A major concern is the maintenance of safety-critical equipment. Only 23% of organizations report completing these activities on schedule. Even more concerning, just 9% of respondents feel confident they are fully aware of major accident hazards (MAHs) across their assets. This lack of visibility is exacerbated by aging facilities, with 39% of professionals citing it as a growing risk factor.

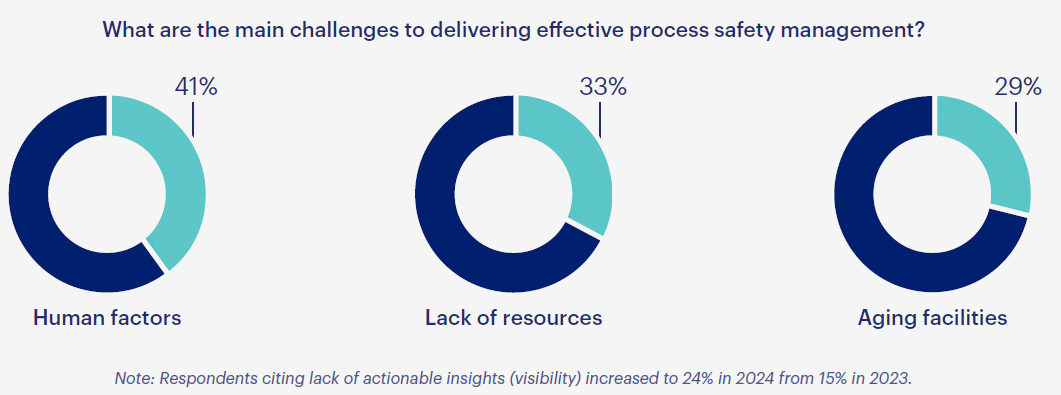

Human factors remain a dominant challenge, with 41% of respondents identifying training and competency gaps as the top challenge to effective PSM. As experienced operators retire, preserving their knowledge becomes crucial. New hires often lack the situational awareness to detect subtle warning signs that could prevent incidents. A seasoned operator might recognize a faint vibration or unusual noise and respond immediately – nuances that less experienced personnel may overlook.

Addressing these issues requires proactive workforce development, operational discipline, and standardized processes to ensure critical knowledge is retained and consistently applied.

Why Compliance Isn’t Enough

While regulation plays a critical role in reducing risk, the report highlights that 56% of organizations still view compliance as an obligation rather than an opportunity to drive broader safety improvements. However, compliance alone is not enough to fully mitigate potential incidents – particularly as plants age and external risks increase.

In the past, process safety was often seen as a box to check for regulators. Today, it intersects with environmental, social, and governance (ESG) goals. Failing to address process safety risks can lead to environmental damage, reputational harm, and financial losses. As a result, more companies now see PSM not only as a safety measure but as a key driver of long-term resilience and business success.

Moving Beyond the Status Quo

Bridging the gap between process safety goals and operational realities requires a more comprehensive approach to risk management. Digital solutions offer an effective way to capture knowledge, control operational risks and standardize processes. So, if the value of digitalization is widely recognized, why haven’t more organizations adopted such solutions? The answer is simple – technology alone doesn’t solve the problem. Several factors contribute to the hesitation:

- Resistance to change – Long-standing employees may be reluctant to transition to unfamiliar digital platforms.

- Lack of clarity – Companies may struggle to identify which digital tools will deliver the most value.

- Over-reliance on manual processes – Paper-based systems and outdated procedures persist, limiting visibility into critical safety data.

Despite these barriers, the benefits of digitalization are clear. 87% of respondents believe that digital tools improve risk awareness, and 80% believe these solutions reduce vulnerability to major accident hazards (MAHs).

How Voovio Can Help

Aging facilities, retiring experts, and a less-experienced workforce create a perfect storm for increased incidents, productivity loss, and operational risks. While many organizations have taken steps to address process safety, gaps persist, and existing solutions often fall short of predicting and preventing MAHs.

To move forward, companies must go beyond basic risk assessments and reactive safety measures. Digital solutions that are simple to deploy and easy to adopt provide an opportunity for PSM to not only reduce incidents and ESG risks but also drive operational efficiency and continuity.

At Voovio, we help process industry leaders close the gap between experienced operators and new hires. Our immersive training and digital simulations capture critical knowledge, enabling operators to practice procedures in a risk-free environment. This ensures that valuable expertise is preserved and new workers gain the skills they need before stepping onto the plant floor.

By adopting tools like Voovio, companies can:

- Reduce operational risks by enhancing workforce competency

- Minimize downtime through consistent training and standardized procedures.

- Improve visibility into potential hazards, ensuring safety-critical maintenance is completed on time.

Ready to strengthen your process safety strategy?

Contact us today to learn how Voovio can help your organization reduce risks and improve performance.