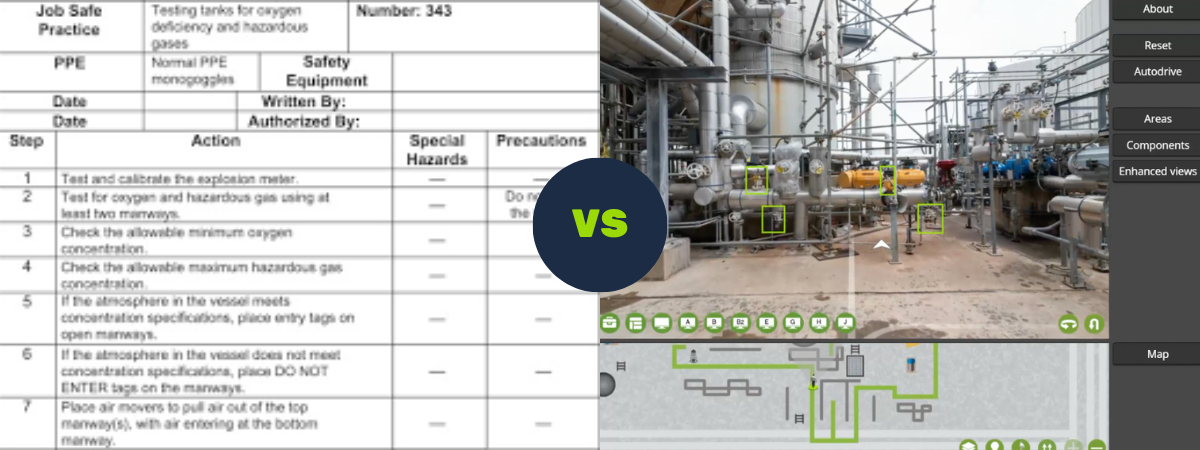

Many of our customers here at Voovio have spent years using written procedure manuals to train and onboard operators, leaning on traditional providers like GP Strategies, TPC Training, TDS and MTS World. For decades, such vendors have enabled plants to design, document and transfer knowledge – using written manuals to map processes. However, with a rapidly growing number of new staff entering the workforce as part of the “great crew change” we’re seeing a shift in the way onboarding takes place – with plants looking for more efficient and immersive methods such as digital simulators, or what we call “enhanced reality”. This doesn’t mean that manuals are going to be replaced, but it’s definitely worth exploring the pros and cons of each and discussing what these different methods bring to the table.

What are written manuals good for?

Having spoken to hundreds of leaders in manufacturing and oil and gas, we’ve found that operations professionals tend to use written manuals as a great way to “simplify the complex”. In addition to documenting the process technology, written procedure manuals show new operators how to:

- Break the whole process down into more digestible parts.

- Learn those different parts at a reasonable pace.

- Put the parts back together to complete the process.

This works well because it allows trainees to realize that the new jobs they are learning are complex and very important. Manuals are very technical and can be intimidating at first glance, however, these manuals give a basic understanding of how different components/ equipment/ process parts interact and work together in the context of an entire plant process.

What about digital simulators like Voovio?

One thing is understanding the different parts of a process – but learning how to interact with that process is a different challenge. Using Voovio, operators can see processes virtually – quickly grasping what it looks like in the field – changing it, manipulating it and working with it, which significantly builds operator confidence. In addition, the operator can learn all this without relying on a trainer or subject matter expert availability; not to mention, simulators are far more stimulating than working with a static procedure manual.

Whether it’s equipment startups, swaps, running different processes, locking them out, or cleaning them – Voovio enables trainees to practice multiple times to build their competency and go out and do it for real – as well as nailing down the exact steps required to do a task correctly every time. This means a new operator doesn’t pick up shortcuts or variabilities in procedure execution, which can lead to expensive and dangerous mistakes.

One or the other, or both together?

Voovio simulators efficiently and effectively give the operators confidence on the pieces of equipment/process they are working with while showing the exact steps to correctly execute a procedure. Simulators provide something very complimentary to the existing written procedure manuals which remain the foundation of the process technology.

Want to see a demo? Contact us today.